How to Streamline Order Fulfillment Operations

What’s the key to efficient order fulfillment operations? How is Amazon offering same day delivery or 2-day delivery? How can they manage order fulfillment so fast?

Their secret lies in the strategic placement of Amazon fulfillment centers. The giant retailer has strategically built warehouses nearby locations with a high population density. This strategy makes products readily available from any geographical location. Moreover, they’ve automated a big share of their warehouse operations. Warehouse robots pick and pack incoming orders, which speeds up order fulfillment.

But what about smaller retailers? How can small and medium-sized retail businesses compete with giant retailers’ lightning-fast order fulfillment process?

Even though Amazon’s delivery and order fulfillment strategy might not be suitable for smaller businesses, there are ways to streamline order fulfillment operations and speed up order delivery.

Table of Contents

The Role of Order Fulfillment in Supply Chain Management

Order fulfillment has a leading role in supply chain management. In e-tailing, customers’ online orders power all logistics processes. Once someone makes an online purchase, orderpickers drive through the warehouse or fulfillment center to the exact location of the respective product. Then, warehouse staff packs and loads the products into delivery vehicles. Finally, last mile carriers and delivery drivers handle the transportation of the orders to the end customer.

One of the end goals of supply chain management is to get the ordered products to the customers in the fastest and cheapest way possible. To achieve this goal, all 6 steps in the order fulfillment process must be optimized.

What Are the Six Steps in the Order Fulfillment Process?

- Receiving inventory: The manufacturer delivers the ordered inventory. Once merchandise reaches your warehouse, you must check the shipping manifest and the received products.

- Storing inventory: After inspecting the received order, you must label it and store it. Before placing each item on the shelves of your fulfillment center, you have to fill in a receiving note. By doing so, you’ll always know where in your warehouse to look for a specific inventory item for easy pick-up.

- Picking inventory items: As products get ordered by customers, create a picklist and hand it over to the order pickers. If you’re using digital labels, your orderpickers can scan the items on the picklist and instantly find out where each item is located in the fulfillment center. The pickers will then move the picked orders to the packing station in your warehouse.

- Packing inventory items: At this stage, the ordered products are packed, packaged, and prepared for their last-mile delivery journey towards the end customer.

- Order shipping: After packing, customers’ orders are loaded into delivery cars. You can choose to handle shipping and last-mile delivery in-house or outsource it to last-mile carriers such as UPS, DHL, USPS, etc.

- Reverse logistics processes: Finally, all that’s left to do is handling product returns efficiently.

How to Make Order Fulfillment Operations More Efficient

A complex routing solution might be all you need to make order fulfillment operations more efficient. Route4Me routing software can help any logistics-intense business improve supply chain management – from middle mile logistics, distribution, and warehousing operations to last-mile delivery and reverse logistics processes. Here’s how you can optimize order fulfillment with Route4Me in 5 easy steps:

1. Switch to Digital Labels and Use In-App Barcode Scanner

According to Fortune Business Insights, the smart label market is expected to reach USD 13.91 billion by 2026.

Digital labels with e-ink barcodes will help you save time and money. Instead of printing and replacing labels periodically, you can update electronic shelf labels (ESLs) with a click of a button as often as you’d like – with minimal effort. Furthermore, ESLs can help you reduce payroll expenses and eliminate siloed data between your eCommerce platform and fulfillment centers.

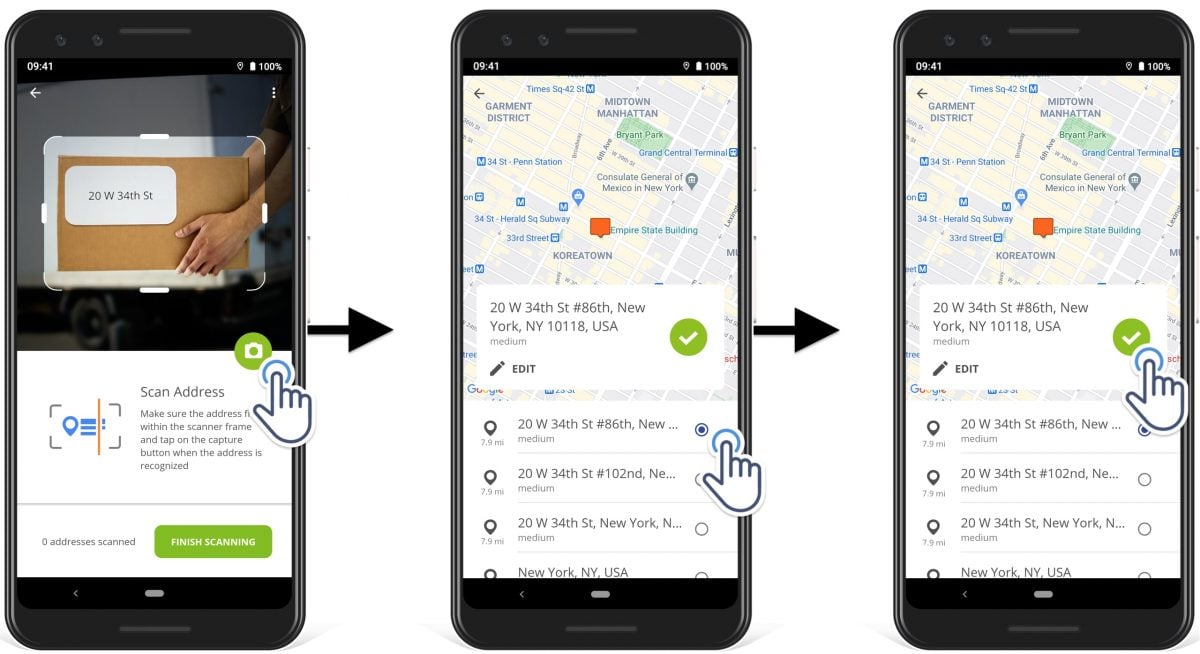

The Route4Me iOS and Android route planner apps have a built-in e-ink barcode scanner that you can use to speed up data input, minimize errors, and revamp your order fulfillment processes.

2. Optimize Routes for Warehouse Orderpicking to Speed Up Order Fulfillment

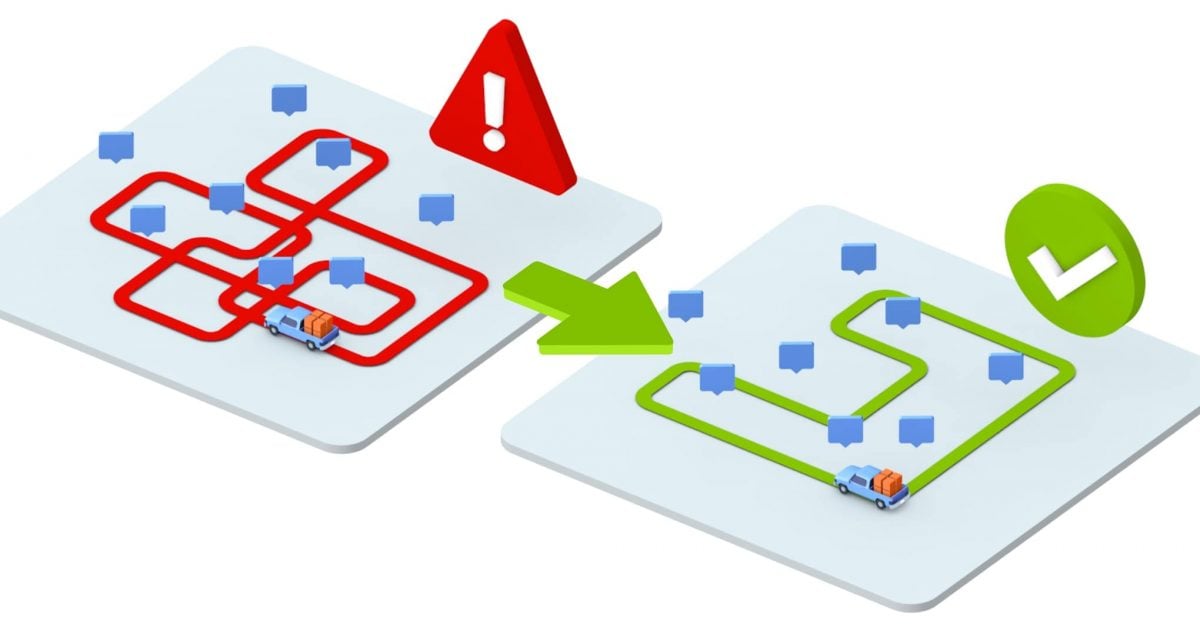

To ensure your warehouse workers don’t have to wander through the fulfillment center too much when looking for a product, you should consider planning and optimizing warehouse routes for your order-pickers. By finding the fastest pick-and-pack routes to accelerate order fulfillment processes, your warehouse staff will be more productive and efficient.

3. Sync eCommerce Online Orders With Route Planner

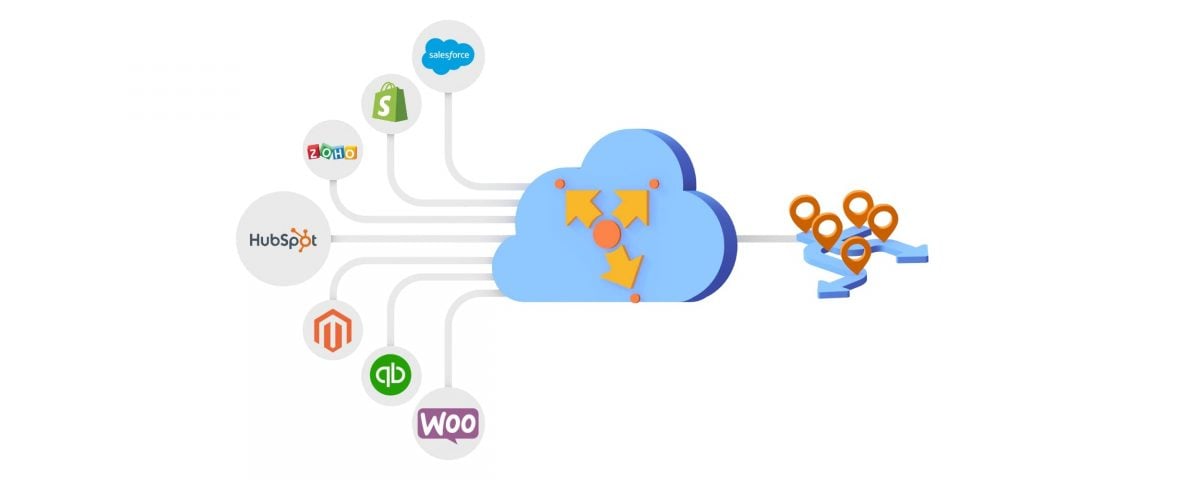

To make order fulfillment even easier and faster, integrate your eCommerce platform with the route planner you’re using. By doing so, every new order will be automatically added to the route planner. With all the data at hand, you will simplify warehouse operations, order routing, and last mile optimization.

The Route4Me route planner integrates seamlessly with eCommerce platforms such as:

Moreover, with Route4Me, you can also:

- Color-code eCommerce orders

- Set progressive order statuses

- Schedule and reschedule multiple orders at once

- Create order territories

- Dynamically insert orders into planned routes

- Add delivery information to each order

- And more!

4. Create Optimized Routes With Online Orders for Last Mile Delivery

As soon as you sync online orders with your route planner, you can start mapping customers’ addresses into the most profitable driver routes. Route4Me routing software will help you plan and optimize multi-stop routes tailored to your specific operational needs. With Route4Me, you can plan routes that account for optimization constraints such as:

- Customer availability

- Even workload distribution

- Number of delivery drivers

- Maximum distance per route

- Order priority

- Number of boxes per delivery car

- Vehicle loading and carrying capacity, etc.

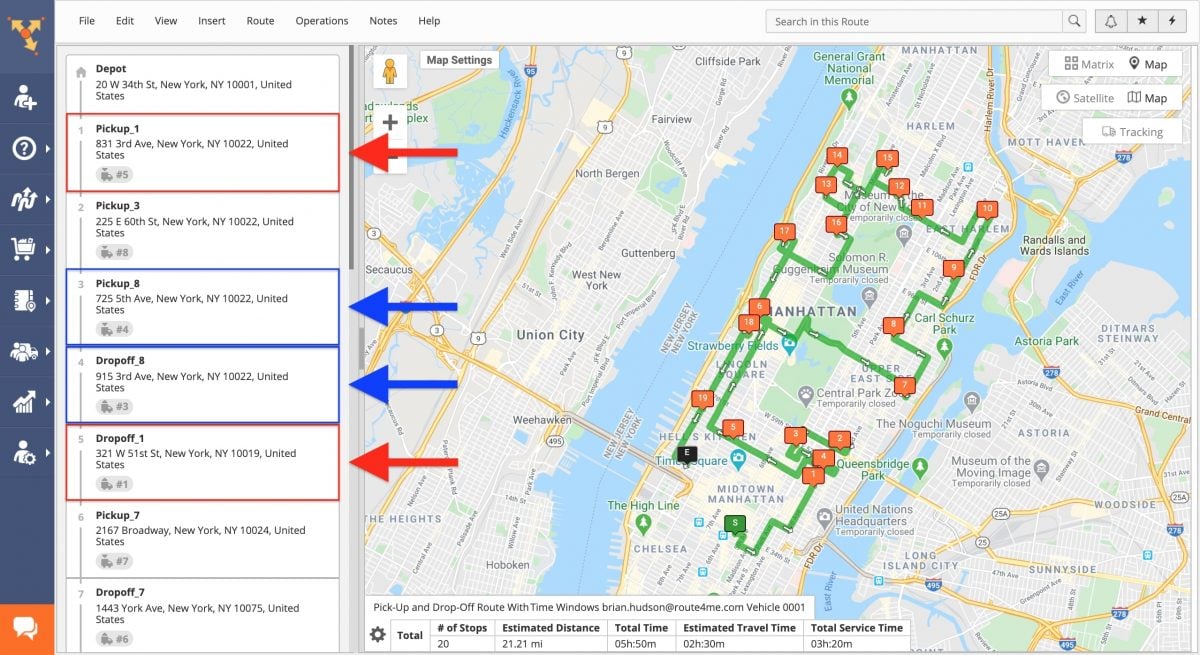

5. Optimize Reverse Logistics Routes for Product Returns

Ideally, you can handle product returns and package pick-ups at the same time as package drop-offs. Although it might sound complicated, routing pickups and dropoffs in one go doesn’t require additional route planning efforts from your side. With Route4Me routing software, you’ll have optimized reverse logistics routes in minutes.

You can start optimizing your order fulfillment processes with Route4Me today. Sign up for a free trial!