Pickup And Delivery Route Optimization – Load Capacity Optimization

Pickup and Delivery Route Optimization helps you the most efficient way to load and unload orders while meeting capacity requirements. Even with just 10 stops, millions of routing combinations are possible, making optimization essential. Route4Me’s advanced algorithm simplifies this by automatically generating routes based on vehicle capacity and order details. Just import pickup and delivery addresses with capacity data, and Route4Me creates the most efficient optimized pickup and delivery routes.

Table of Contents

Plan Pickup And Delivery Routes – Define Operational Constraints

To plan efficient pickup and delivery routes, you can set physical constraints such as maximum pieces, volume, and weight in either an Optimization Profile or manual settings. Once defined, Route4Me will automatically consider these constraints when creating your routes to ensure they meet the operational requirements.

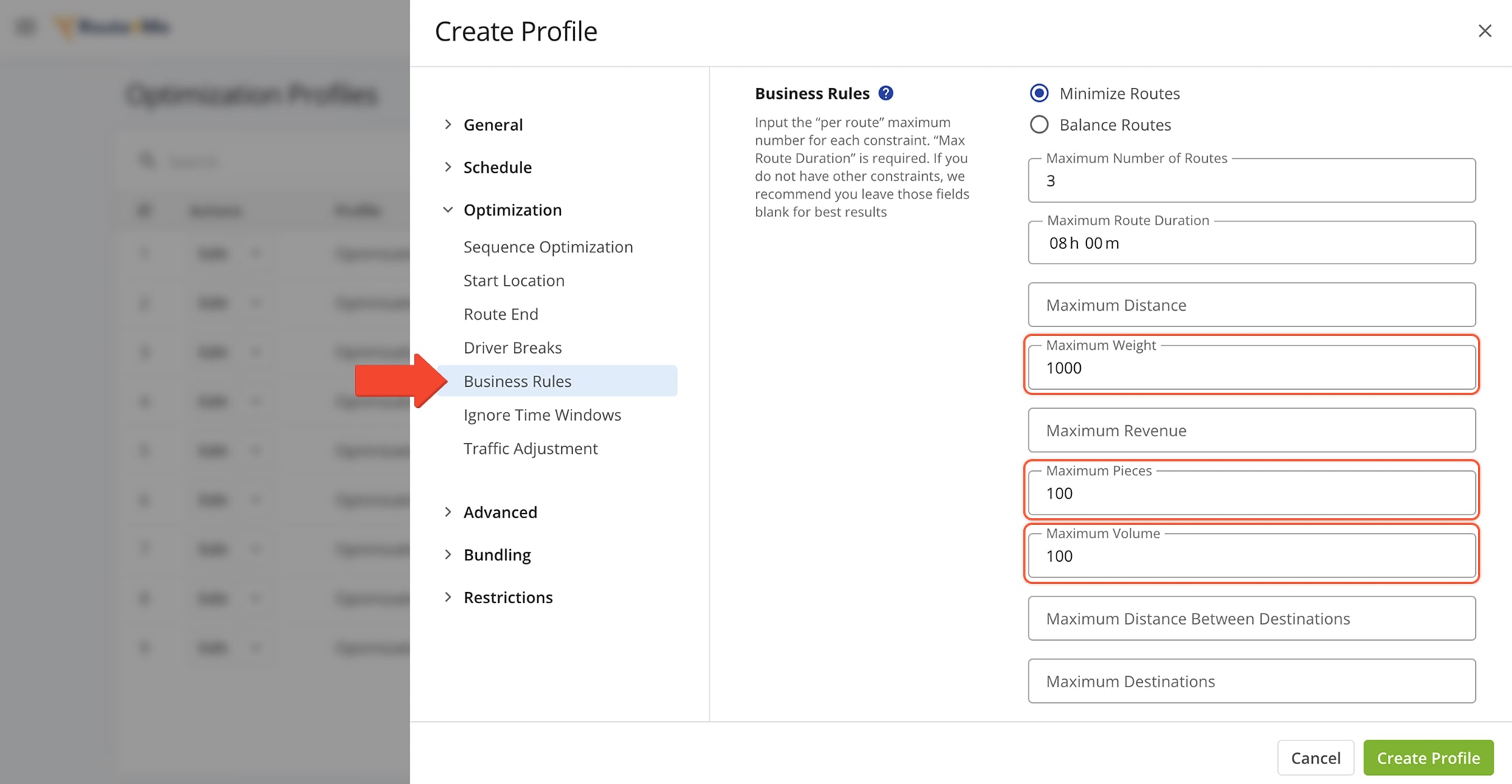

Define Constraints In An Optimization Profile

Click “Optimization Settings” > “Optimization Profiles” in the Navigation Menu. From your Optimizations list, click “Create Profile” or “Edit“. Then, from the Profile Editor panel, open the “Optimizations“‘ tab and click “Business Rules“.

Define the maximum pieces, maximum volume, and maximum weight allowed per route in the Optimization Profile. When you apply the Profile, Route4Me will automatically account for these physical constraints when planning your pickup and delivery route. NOTE: Learn more about planning routes with operational constraints.

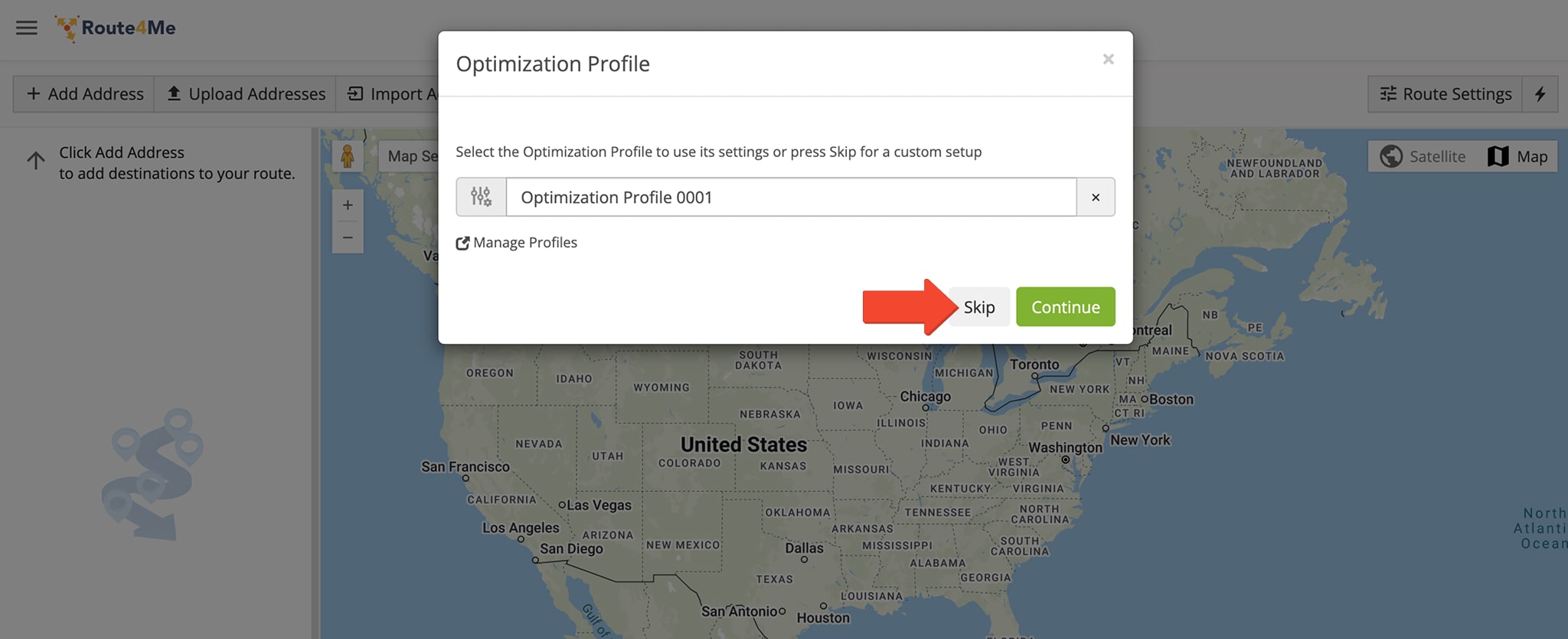

Define Constraints In Manual Optimization Settings

Click “Dynamic Routing” > “Plan New Route” in the Navigation Menu. When prompted to select your route planning method, choose “Upload a File” or “Import Data“. Then, when prompted to select an Optimization Profile, click “Skip” to customize the route’s optimization settings.

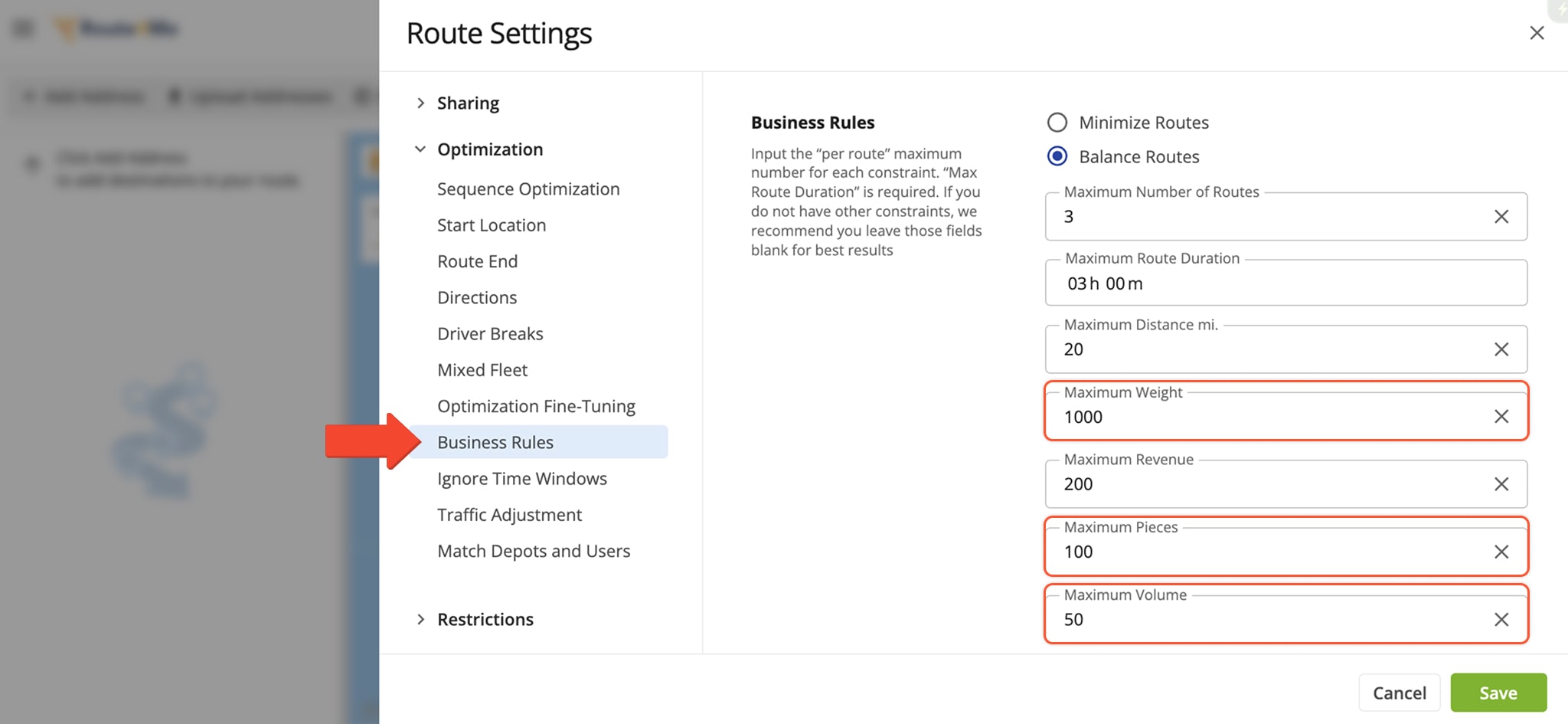

Next, click the “Optimizations” tab, then enter capacity limits under “Business Rules“: maximum pieces per route, maximum volume per route, and maximum weight per vehicle.

NOTE: Learn more about mixed fleet route optimization.

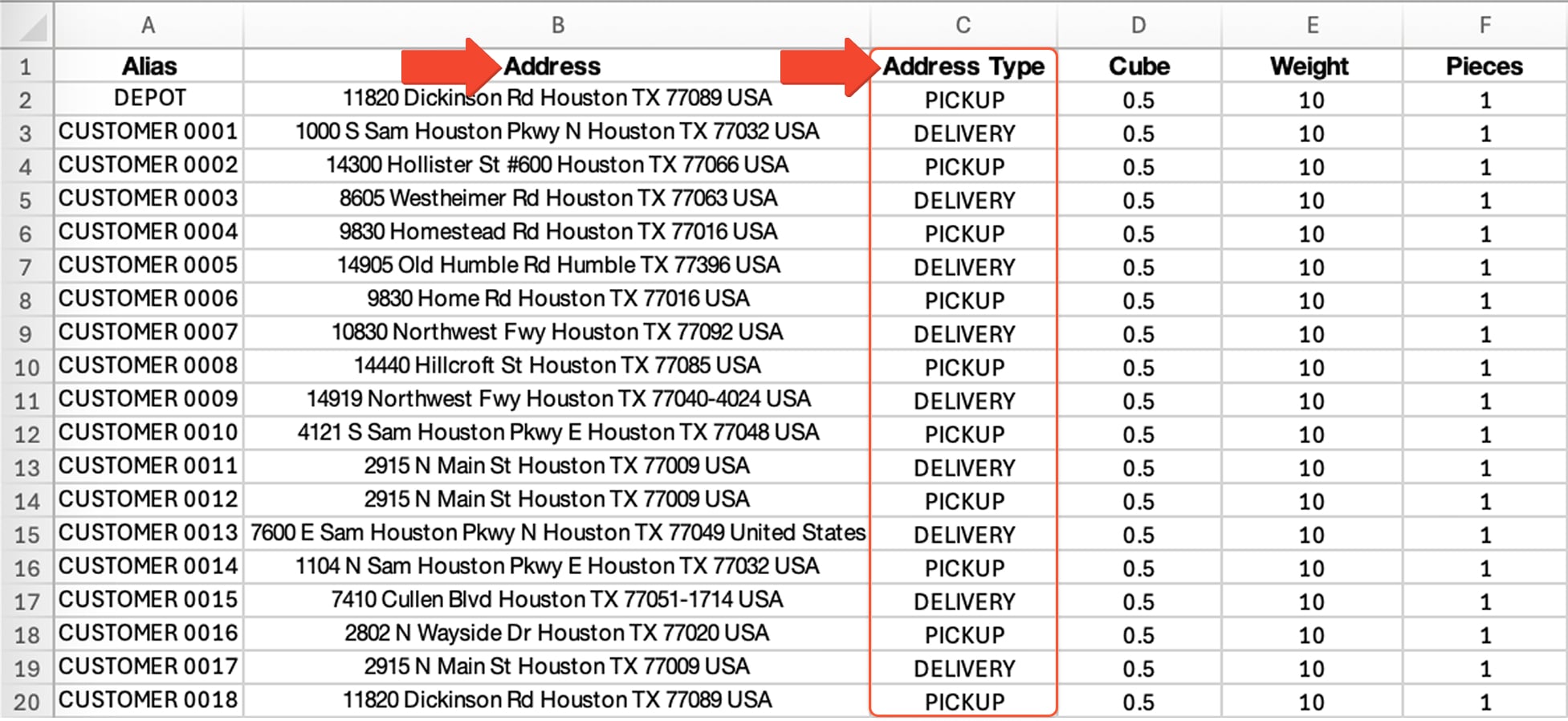

Then, import pickup and delivery addresses with vehicle capacity requirements using a CSV or XLS file. Include a mandatory “Address” column with the locations you want to route, and a mandatory “Address Type” column labeled with either “PICKUP” or “DELIVERY” (in all caps) for each stop.

NOTE: Learn more about Route4Me’s spreadsheet formatting requirements.

Review Pickup And Delivery Route Capacity Constraints

To ensure that your routes align with operational capacity limits, Route4Me automatically factors in both the most efficient route sequencing and the capacity constraints of each vehicle. You can review these constraints in the Routes List, Route Manifest, or Route Export to ensure optimal planning and performance for pickups and deliveries.

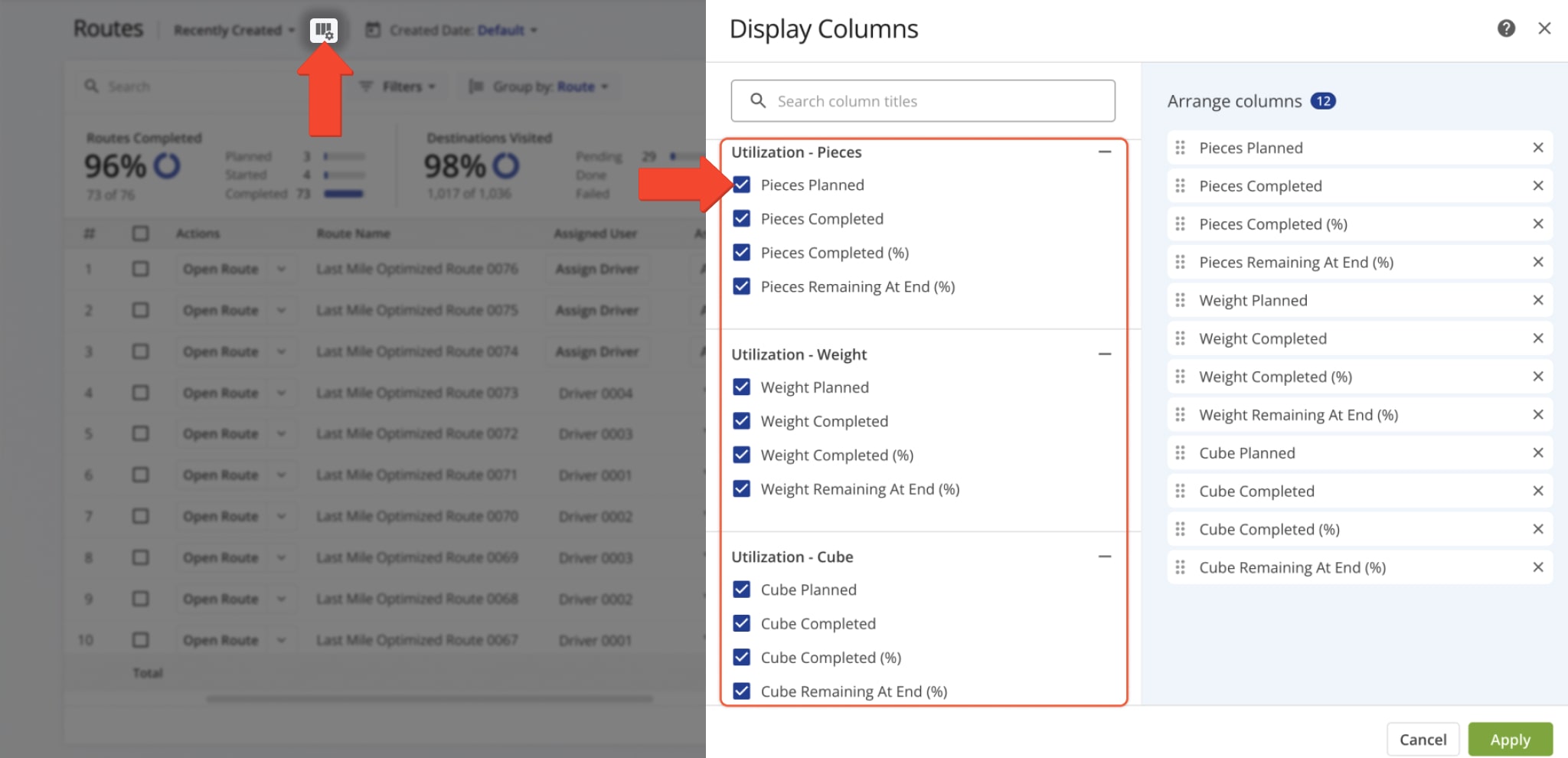

Review Constraints From Routes List

To view operational capacity constraints in your Routes List, click the Column Icon to open the “Display Columns” panel. Then, check the boxes next to the capacity constraints you wish to view. To learn more about each constraint, refer to the table below.

| Capacity Constraint | Description | |

|---|---|---|

| Utilization – Pieces | ||

| Pieces Planned | Total number of planned pieces across all destinations on scheduled routes (visible only if the assigned vehicle has a capacity profile with piece limits). | |

| Pieces Completed | Total number of planned pieces that have been completed on the route, marked as “Done” via the Mobile App. | |

| Pieces Completed (%) | Percentage of the total planned pieces that have been completed by the end of the route. | |

| Pieces Remaining At End (%) | The percentage of planned pieces that remain incomplete by the end of the route. | |

| Utilization – Weight | ||

| Weight Planned | Total planned weight of all destinations on scheduled routes, shown only if the assigned vehicle’s capacity profile includes weight values. | |

| Weight Completed | Total weight of planned destinations that have been completed, marked as “Done” via the Mobile App. | |

| Weight Completed (%) | Percentage of the total planned weight that has been completed, based on destinations marked as “Done” via the Mobile App. | |

| Weight Remaining At End (%) | The percentage of planned weight that was not completed by the end of the route. | |

| Utilization – Cube | ||

| Cube Planned | Total cubic volume of all destinations on scheduled routes (visible only if the vehicle profile includes cube capacity). | |

| Cube Completed | Total cubic volume completed across all destinations marked as “Done” via the Mobile App. | |

| Cube Completed (%) | Percentage of the planned cubic volume that has been completed. | |

| Cube Remaining At End (%) | Percentage of the planned cube volume that remains unfulfilled after all marked “Done” destinations are completed. | |

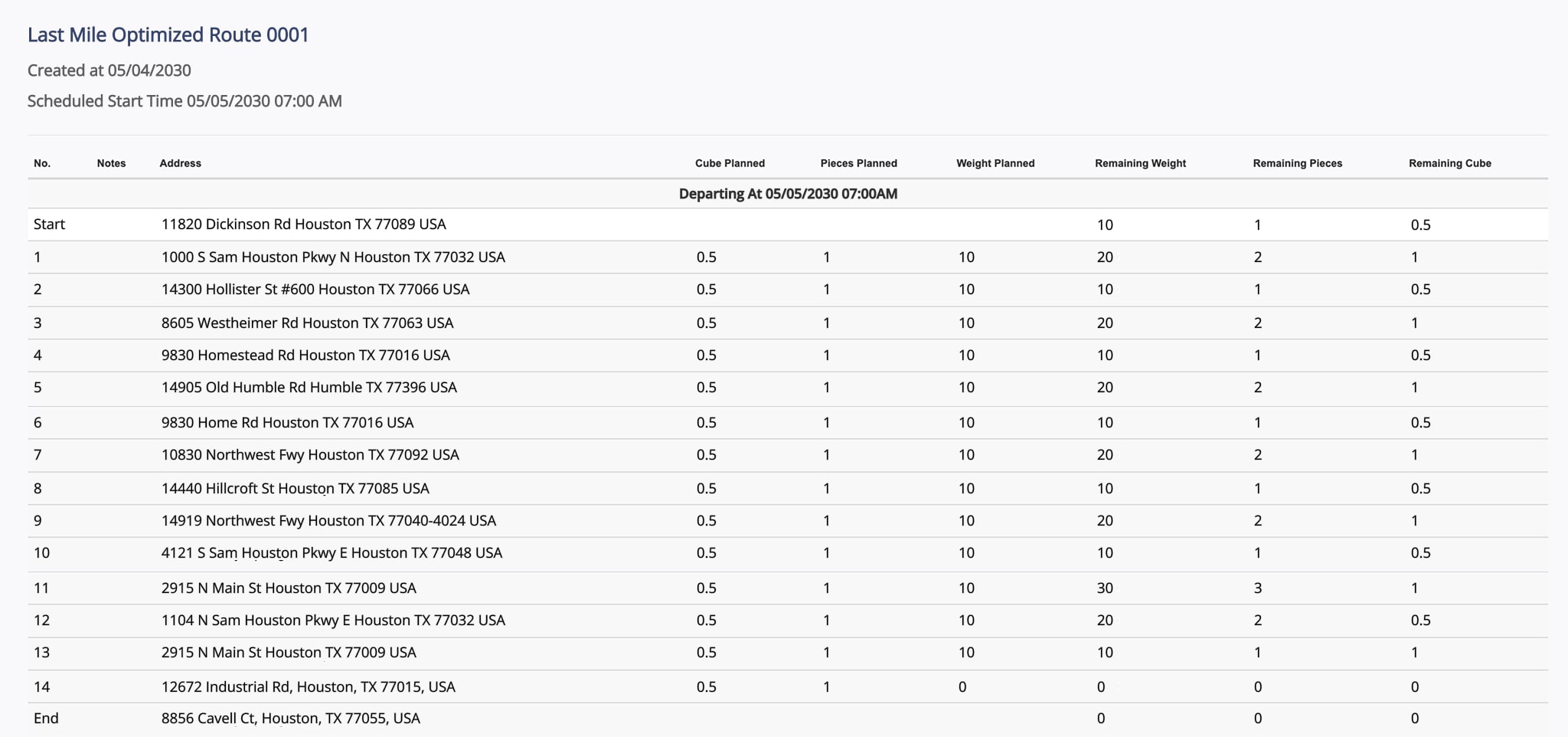

Review Constraints From Routes Manifest

Your Route Manifest also provides data related to route capacity constraint. From your Routes List, click the Down Arrow button next to the route you wish to review, then select “View Manifest“. You can customize the Route Manifest by selecting the columns you want to appear.

NOTE: You can also access your Route Manifest from the Route Editor and the Routes Map. Learn more about accessing and working with Route4Me’s Route Manifests.

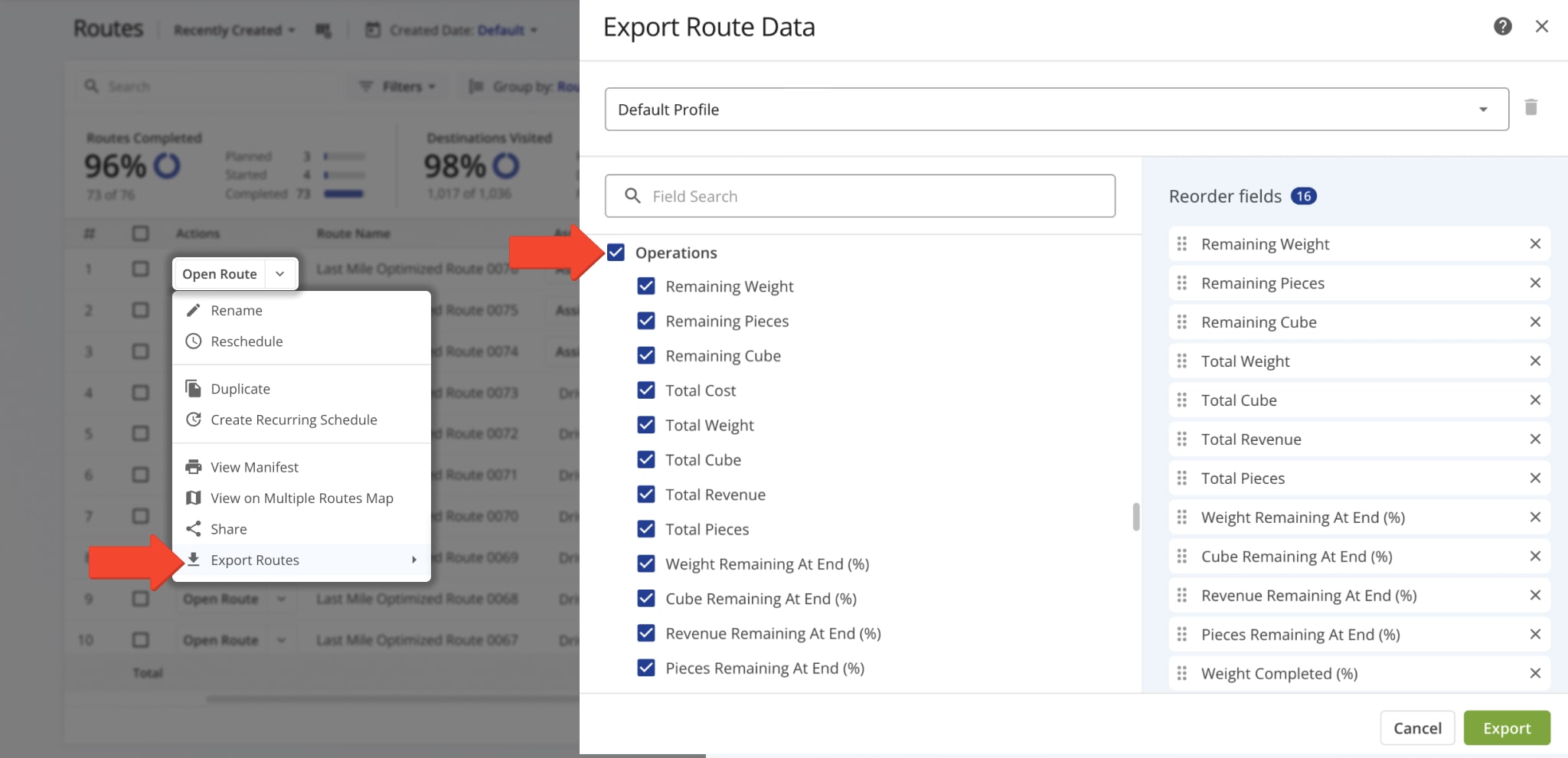

Review Constraints From Route Export

Finally, you can view operational constrains when you export a route. From your Routes List, click the Down Arrow button next to a route, then select “Export Routes“. In the “Export Route Data” panel, be sure to check the boxes in the “Operations” section to include operational capacity data in your export.

NOTE: You can also export route data from the Route Editor and the Routes Map. Learn more about exporting routes.

Enable Mixed Pickup And Delivery Demands

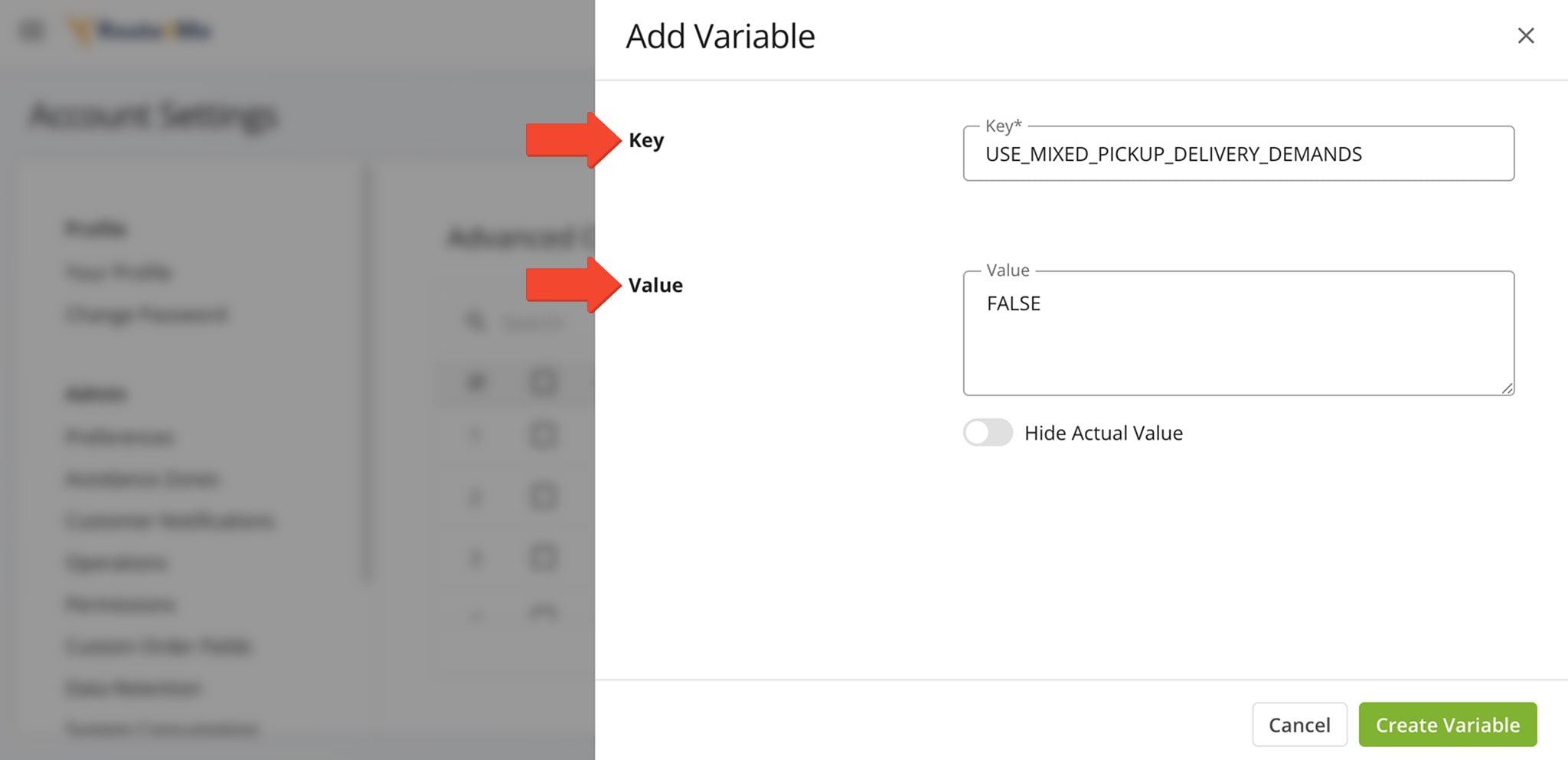

Route4Me also supports Mixed Pickup and Delivery Demands, allowing for independent or connected pickups and deliveries within capacity routes. To enable this feature, open your Advanced Configuration Editor, add the “USE_MIXED_PICKUP_DELIVERY_DEMANDS” configuration, and set it to “True” or “False” to customize your route planning.

When set to “True“, pickups and deliveries are treated as separate – picked-up items remain on the vehicle until the route ends, and all deliveries are loaded before the route starts. When set to “False“, pickups and deliveries are connected, allowing picked-up goods to be delivered during the route.

Open Advanced Configuration Editor

Pickup And Delivery Route Optimization FAQs

Explore the most common questions users have about optimizing Pickup and Delivery routes.

Simply add the “Pickup” and “Delivery” columns to your route spreadsheet. Route4Me will detect and optimize routes based on these addresses and your route settings.

Pickup and delivery routing is free with Multiple Driver Route Optimization. To use capacity planning with pickup and delivery optimization, enable Cube, Weight, and/or Pieces constraints separately.

No, vehicle assignment does not impact pickup and delivery capacity optimization. The system optimizes routes based on your set capacity constraints (Cube, Weight, and Pieces). However, vehicle type can affect other route parameters, such as when using Mixed Fleet Optimization or commercial vehicle profiles.

Route4Me supports the following constraints for capacity optimization: Cube (volume), Weight, and Pieces (items). You can use these constraints individually or together, as long as you have them enabled in your account.

Yes, simply add the “Address Type” column to your route spreadsheet and specify “PICKUP” or “DELIVERY” for each address. The system will optimize routes accordingly.

To enable Mixed Pickup and Delivery Demands optimization, add the advanced configuration “USE_MIXED_PICKUP_DELIVERY_DEMANDS” to your account and set it to “True” to enable or “False” to disable.

Pickup and Delivery routing involves loading goods at one location and unloading them at another, with the option for pickups and deliveries to be independent or in reverse order. Pickup and Dropoff routing involves picking up an item at one location and delivering it to another, where the pickup always occurs before the dropoff.

The Pickup and Delivery Problem is an extension of the Vehicle Routing Problem, with additional constraints related to vehicle capacity and order requirements. It optimizes the sequence of pickups and deliveries to prevent overloading or underloading the vehicle.

Full Truckload (FTL) route optimization uses a truck’s full capacity, while Less Than Truckload (LTL) route optimization uses part of the truck’s capacity.

For both FTL and LTL, pickup and delivery routes require additional optimization to account for the dynamic vehicle capacity after each stop. This ensures efficient planning, whether using full truckload and less than truckload routing.

Visit Route4Me's Marketplace to Check out Associated Modules:

- Route Optimization

Max Cube per Route

- Route Optimization

Max Pieces per Route

- Route Optimization

Max Weight per Route

- Route Optimization

Max Revenue per Route

- Route Optimization

Commercial Vehicle & Truck Routing

Last Updated: