Fuel Delivery Optimization – Plan Fuel Delivery Routes To Maximize Capacity Utilization

Fuel delivery providers face challenges traditional routing algorithms can’t solve. Fuel tankers often exhaust their capacity before completing routes, forcing premature refill stops, increased fuel consumption, and longer route distances and delivery times. Route4Me’s fuel delivery optimization algorithm solves the complexity of optimizing multi-compartment fuel tanker routes while maintaining compliance with safety regulations and maximizing operational efficiency. Keep reading to learn more.

Table of Contents

Fuel Delivery Optimization And Route Planning Overview

Fuel delivery is inherently complex due to multi-compartment tanker trucks, mixed fuel products, variable drop sizes, terminal constraints, and strict delivery schedules. Our fuel delivery optimization system is built to solve these challenges at scale.

Route4Me automatically accounts for fuel capacity, compatibility, delivery sequencing, gravity-fed versus pump-off constraints, terminal availability, and more. By modeling real-world fuel hauling conditions and applying intelligent refill decision-making with configurable minimum and maximum thresholds, our system generates optimized routes that reduce deadhead miles, prevent cross-drops, and enable your vehicles to serve more customers per day in less time and with fewer refill stops.

Plan And Optimize Fuel Delivery Routes With Enterprise TMS

With Route4Me, you don’t have to manually configure complex fuel delivery routing logic. Simply get in touch with one of our routing experts and provide the operational data and business rules for your fuel delivery scenario, and we’ll handle the rest.

Whether you’re optimizing single-day fuel routes or recurring multi-day fuel delivery cycles, Route4Me translates your operational constraints into field-ready, safe, compliant, and mathematically optimized routes.

Data And Parameters For Fuel Delivery Optimization

Our system is flexible and supports a wide range of operational data. Companies can optimize routes using as much or as little detail as required, and additional parameters can be introduced at any time. Supported data input types include:

- Vehicle characteristics: capacity, compartment configuration, pump-off capability, product compatibility, vehicle weight and size, etc.

- Fuel product data: fuel types, delivery quantities, minimum and maximum tank thresholds, safety and regulatory constraints, etc.

- Location-level data: depots, terminals, customer sites, underground storage tanks, service time, access restrictions, time windows, etc.

- Business rules: route duration, hours of service breaks and driver shift length, maximum distance between destinations, and more.

Operational parameters such as refill policies, terminal preferences, and delivery priority can also be applied. Our flexible data model provides adaptability without forcing companies into rigid workflows.

Optimized Fuel Delivery Scenarios And Routes

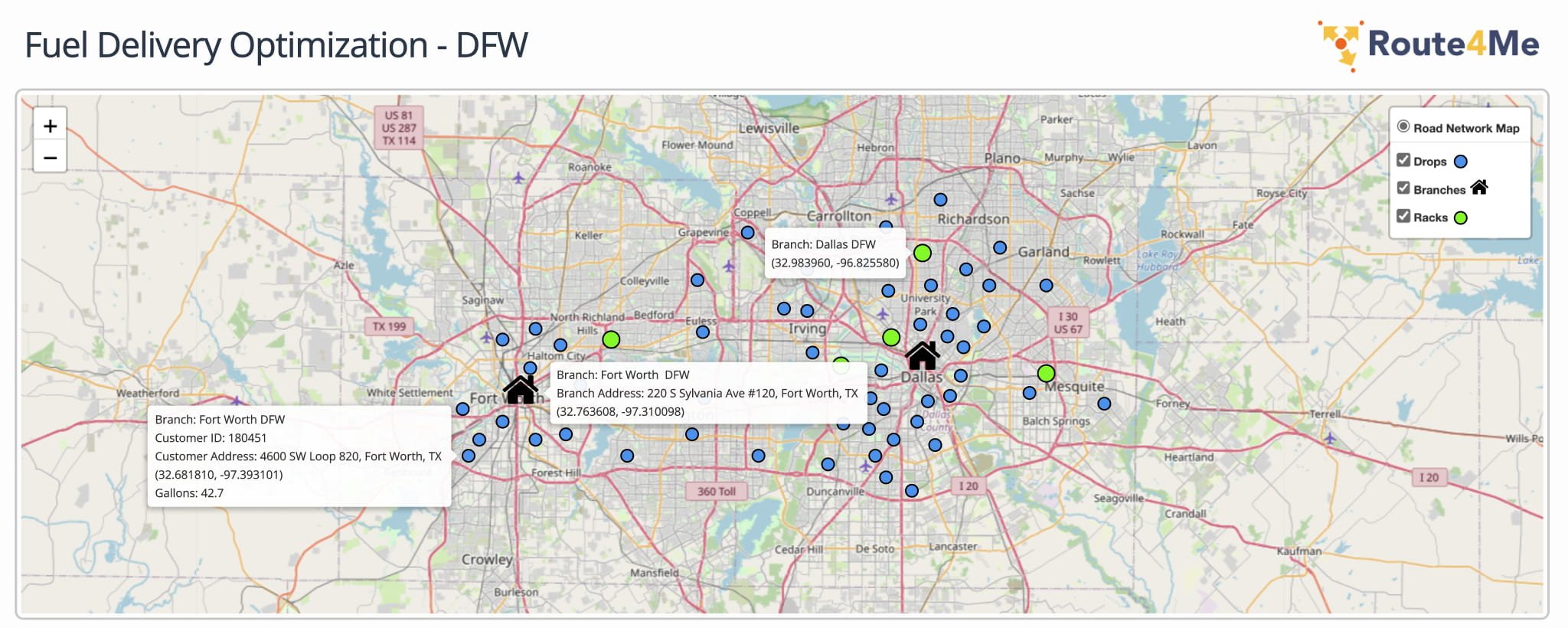

Once your data is optimized, you can see a full breakdown of your fuel delivery optimization scenario. This includes an interactive map showing the locations of company branches, fuel terminal racks available for vehicle refill, and customer location drops.

You can hover over any location visible on your route optimization map to see its associated company branch, address and coordinates, and customer details such as ID number and planned fuel volume.

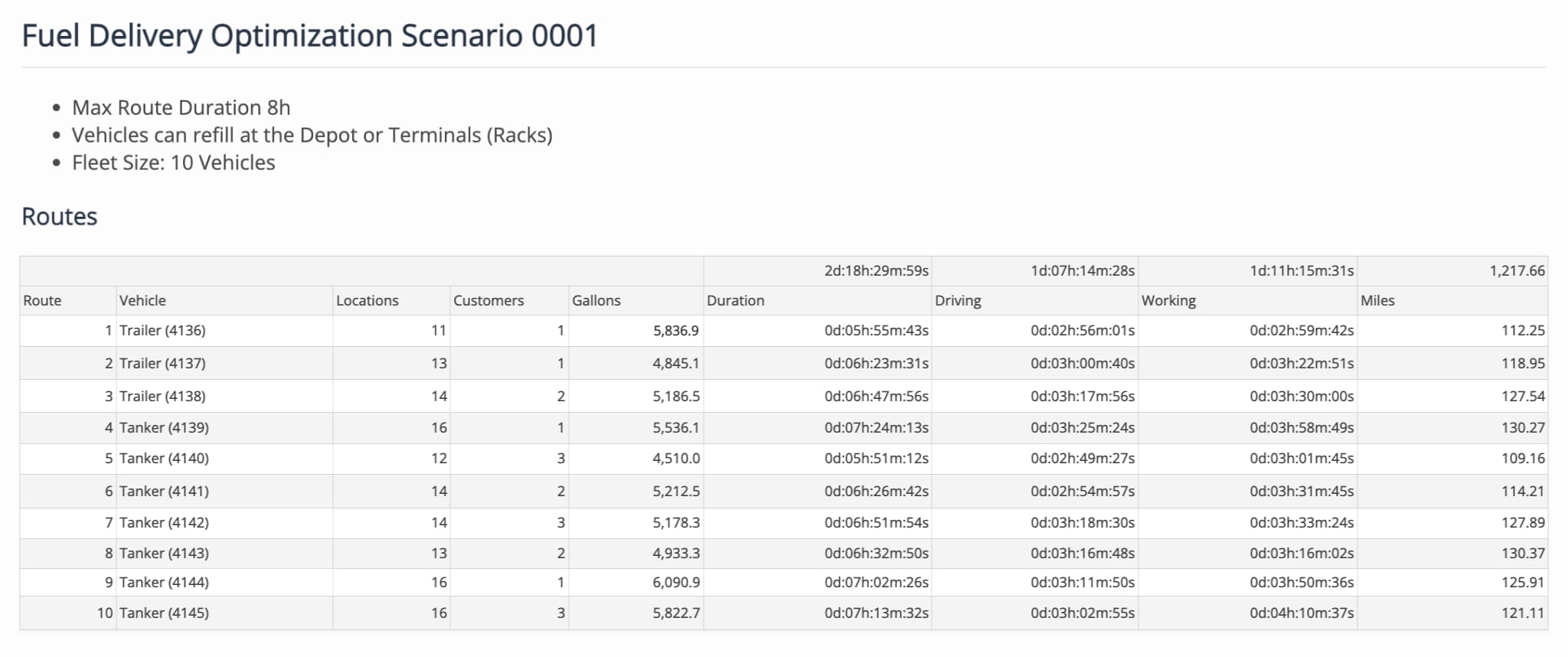

Scenarios include routes assigned to your vehicles. You can see the total number of planned delivery locations (not counting refills), customers serviced, planned gallons of fuel for delivery, and route duration and distance. Each route’s total duration is broken down into “Driving” (travel time), and “Working” (service time) values, with totals shown above the respective columns.

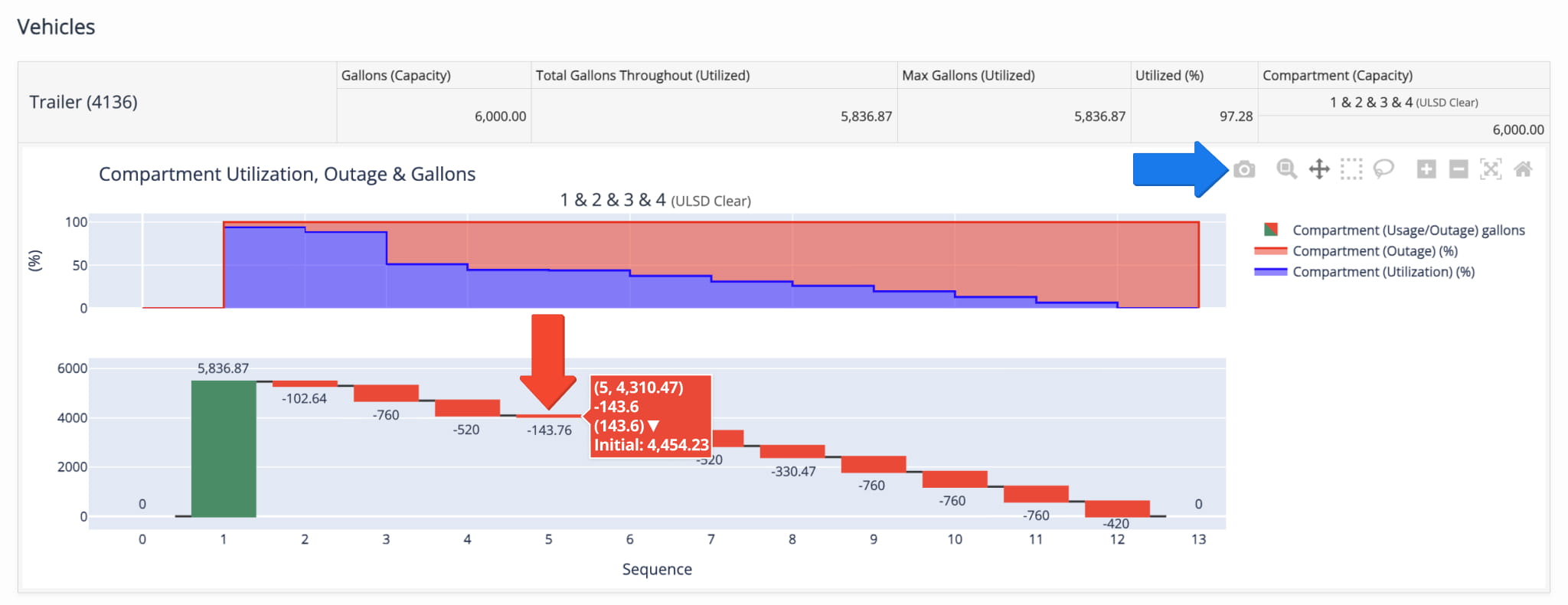

Dynamic fuel level and capacity utilization graphs provide an accurate visual overview of your vehicle’s capacity utilization and outage at each route destination per fuel type and compartment.

You can hover over any data point in the graph to see more detailed information about the change in fuel level at that destination. Refills at racks and depots are shown in green, and drops at destinations are shown in red. Additionally, you can use the control buttons in the top-right to navigate, zoom, and download your fuel utilization graphs.

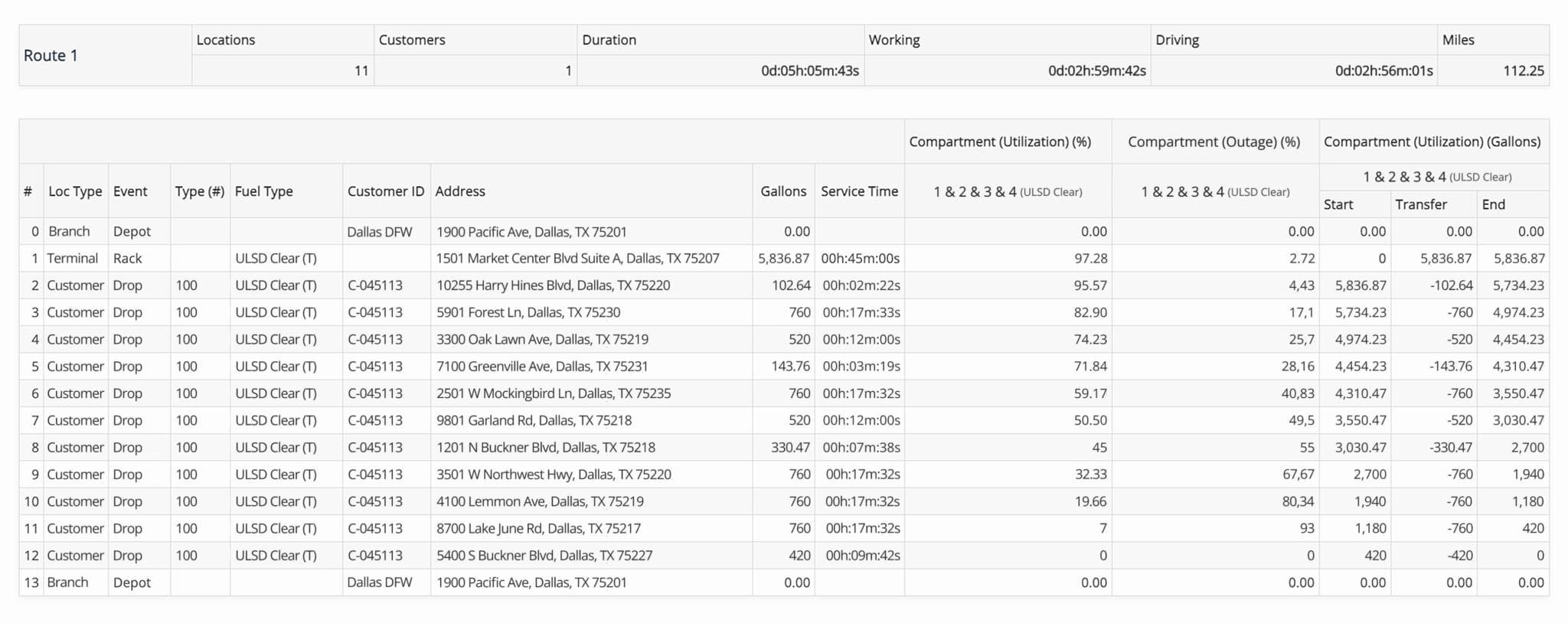

Each fuel delivery route is available as a detailed data sheet broken down by destination location types and events. You can see the fuel capacity values, utilization, outage and service time broken down by destination and compartment.

Utilization and outage values are shown both as total gallons and as a percentage of each fuel compartment’s total capacity. If you have any questions or need more information about fuel delivery optimization, please contact our routing experts.

Glossary Of Fuel Delivery Terms And Hauler Jargon

Fuel delivery, route planning, and optimization are complex processes with specialized terminology. The table below is a glossary of terms used by field employees, fuel haulers, routing experts, and more.

| Term | Description | |

|---|---|---|

| Common Fuel Hauler Terms | ||

| Rack | The loading station at a fuel terminal where tankers load product via top arms or bottom hoses. | |

| Bay | A single loading position under the rack assigned to one truck at a time. | |

| Racked Out | Fully loaded with fuel and ready to leave the terminal. | |

| Dead Rack | A fuel terminal where loading is unavailable due to outages, maintenance, or product shortages. | |

| Going Hot | Loading a volatile fuel product such as gasoline, as opposed to diesel. | |

| Back to the Rack | Returning to the terminal mid-route to reload fuel. | |

| Running the Rack | Loading at multiple terminals or racks during a single shift. | |

| Drop | A delivery of fuel to one customer location or set of tanks. | |

| Multi-Drop | A route with multiple delivery stops. | |

| Splash | A small partial delivery used to top off a tank rather than fully refill it. | |

| Pump-Off | Delivering fuel using the truck’s pump instead of gravity, often required for uphill tanks. | |

| The Stick | A calibrated measuring stick used to manually gauge tank levels. | |

| Stick a Tank | Manually measuring a tank’s fuel level before or after delivery. | |

| Clear | Undyed diesel fuel intended for on-road use. | |

| Red | Dyed diesel used for off-road, agricultural, or heating purposes. | |

| Five-Way | A full load where all tanker compartments carry different fuel products. | |

| Compartment Order | The sequence in which tanker compartments are loaded and unloaded, critical for delivery planning. | |

| Cross-Drop | Delivering the wrong fuel product into the wrong tank, typically resulting in severe consequences. | |

| Turn | A complete delivery cycle: load, deliver, and return to terminal. | |

| Double Turn | Two full delivery cycles completed within one shift. | |

| Graveyard | An overnight fuel hauling shift. | |

| Mid-Route Refueling | Refueling the tanker while actively executing a delivery route. | |

| En-Route Refueling | Operational term for refueling during a route rather than at shift start or end. | |

| Splash-and-Go | An informal term for a quick mid-route fuel top-off. | |

| Turn-and-Burn | A fast refuel or reload performed to maintain a tight delivery schedule. | |

| Hot Fueling | Refueling while the vehicle remains running, used only in specific operational contexts. | |

| Optimization Terminology | ||

| Load-to-Drop Matching | The optimization process of aligning compartment contents with delivery order to minimize pump-offs and crossovers. | |

| Compartment-Constrained Routing | Route planning that accounts for individual tanker compartment sizes and product types. | |

| Product Compatibility Constraint | A routing rule preventing incompatible fuel products from being sequenced in ways that risk contamination. | |

| Drop Sequencing | Optimizing the order of deliveries to align with compartment order and gravity flow. | |

| Gravity-First Optimization | Planning drops so gravity-fed deliveries occur before pump-offs to save time and wear. | |

| Tank Capacity Constraint | Ensuring delivered volume does not exceed underground tank capacity based on stick readings or telemetry. | |

| Minimum Drop Threshold | A rule defining the smallest allowable delivery volume for a stop. | |

| Splash Optimization | Strategically planning partial deliveries to prevent run-outs without overcommitting product. | |

| Run-Out Risk Scoring | A predictive metric estimating how close a customer is to running out of fuel. | |

| Priority Drop | A delivery flagged as urgent due to low tank levels or contractual obligations. | |

| Deadhead Minimization | Reducing empty miles traveled between drops or back to the rack. | |

| Rack-to-Rack Optimization | Planning routes that involve loading from multiple terminals to improve product availability or reduce distance. | |

| Turn Compression | Optimizing schedules to fit more turns into a single shift. | |

| Double-Turn Feasibility Window | The time window in which two full turns can be completed without violating hours-of-service limits. | |

| Terminal Dwell Time | The expected time spent waiting, loading, and staging at a rack. | |

| Bay Availability Constraint | Routing logic that accounts for limited loading bays at terminals. | |

| Hot Load Constraint | Special handling rules applied when loading volatile products like gasoline. | |

| Tank Telemetry Integration | Using live tank level data to dynamically adjust routes and drop quantities. | |

| Forecast-Based Routing | Using historical consumption data to predict future fuel needs and pre-plan routes. | |

| Consumption Curve | The modeled fuel usage pattern of a customer over time. | |

| Multi-Frequency Scheduling | Planning routes where customers require deliveries on different recurring intervals. | |

| Scenario Planning | Simulating alternative routing outcomes before committing loads to trucks. | |

| Optimization Period | The time horizon over which routes are planned and balanced. | |

| Stop Density Balancing | Distributing drops evenly across routes to avoid overload. | |

| Miles-Per-Gallon Optimization | Balancing route efficiency with vehicle fuel consumption characteristics. | |

| Service Time Normalization | Standardizing expected delivery times per stop for accurate routing. | |

| Constraint Relaxation | Temporarily easing optimization rules to resolve infeasible routes. | |

| Exception-Based Reoptimization | Automatically recalculating routes after disruptions like dead racks or late loads. | |

Visit Route4Me's Marketplace to Check out Associated Modules:

- Operations

Advanced Team Management Add-On

- Operations

Audit Logging and Activity Stream