How To Optimize Cross-Docking And Transloading Routes

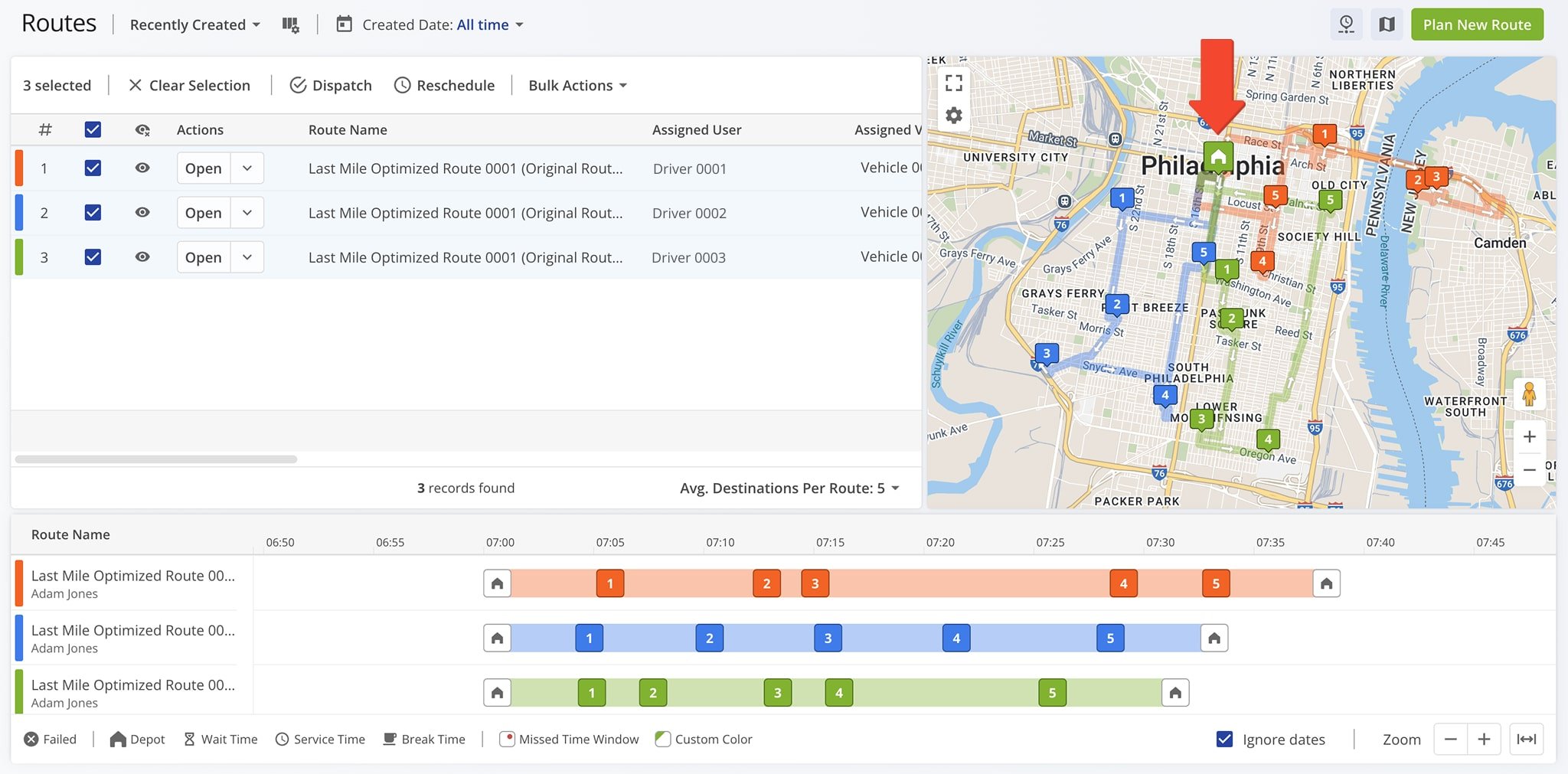

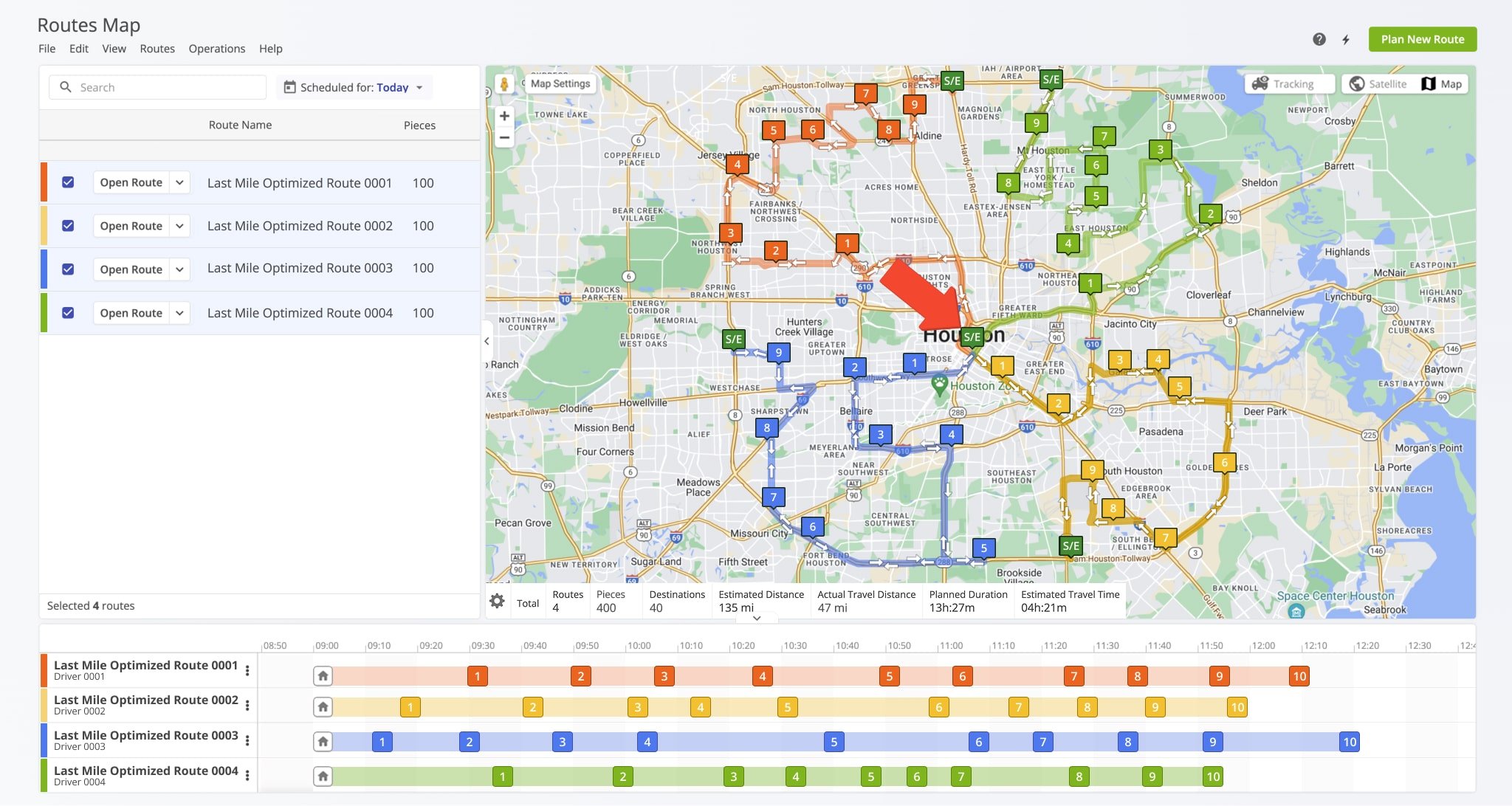

Cross-docking and transloading help businesses streamline logistics by reducing or eliminating warehouse storage through direct inbound-to-outbound product transfers. Instead of sending small shipments from multiple warehouses to every customer, goods are consolidated at a central distribution center, assembled into mixed pallets, and sent out on optimized delivery routes. This method minimizes handling time, reduces overhead, and supports faster last-mile delivery. With Route4Me’s fleet routing software, you can quickly plan both inbound and outbound routes that support complex cross-docking workflows.

With Route4Me’s dynamic routing software, you can streamline cross-docking and transloading operations by planning optimized routes to transport goods from multiple warehouses or vendors to a single distribution center quickly and efficiently. Once inbound goods are assembled into mixed pallets, you can plan optimized delivery routes with the most efficient stop sequences to distribute products to end customers, assembly lines, or any other mapped locations. Depending on your business needs, Route4Me supports various cross-docking types.

For example, Manufacturing Cross-Docking involves a central distribution center receiving goods and materials required for production, then sorting and assembling them into products ready for shipment to customers or other locations. Learn how to plan manufacturing cross-docking routes.

Distributor Cross-Docking: Involves a central distribution center that consolidates inbound products or goods received from multiple vendors into the outbound mixed product pallets. Once each mixed pallet is assembled from the different received product types, it is delivered to the end customer or another production line. Learn how to plan distributor cross-docking routes.

Transportation Cross-Docking : Consolidates shipments from multiple carriers or suppliers (LTL) into full truckloads (FTL) at a distribution center for delivery to end customers. Learn how to plan transportation cross-docking routes.

Retail Cross-Docking: Sorts products from various vendors into mixed pallets for outbound trucks, delivering them to multiple retail stores. Learn how to learn how to plan retail cross-docking routes.

Visit Route4Me's Marketplace to Check out Associated Modules:

- Operations

Advanced Team Management Add-On

Last Updated: